Point to Note of Lubrication and Safety Design

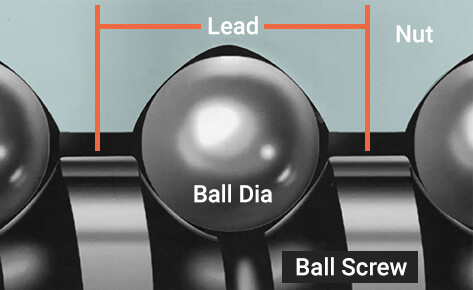

Groove Shape of Precision Ball Screw

When axial play is minimized in conventional screw-nut assemblies, the actuating torque becomes excessive and the operation is not smooth.

The axial play in precision ball screws may be reduced to zero by preloading and a light smooth operation is still possible. Therefore, both low torque and high rigidity can be obtained simultaneously. Ball screws have gothic arch groove profiles which allow these conditions to be achieved.

Groove Shape of Precision Ball Screw

Groove Shape of Precision Ball ScrewLubricating

Adequate lubrication must be provided when ball screw is used, insufficient lubrication will result in contact of metal, which in turn leads to increase of friction and friction loss, thus cause failure of shortening of service life.

Lubricants applied to ball screws can be divided into 2 types, namely lubricating oil and consistent grease. In general speaking, in respect of maintenance, consistent grease will lead to increase of dynamic friction torque linearly along with increase of rotating speed, hence oil lubrication is deemed the better way when speed exceeds 3-5 m/min; however, don’t forget the fact that there have been examples that using grease has been capable of achieving speed of 10 m/min, with respect to the equipment.

| Method | Interval | Check Item | Replenish or Change Interval |

|---|---|---|---|

| Auto Intermittent oil supply | Weekly | Oil level, contamination | Add at each check, as required depending on tank level |

| Grease | Initially 2-3 months | Contamination on entry of chip | Replenish yearly or according to the inspection results |

| Oil bath | Daily | Oil level | To be determined according to consumption |

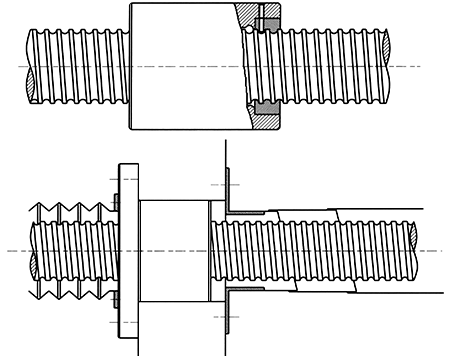

Contaminant Prevention

Any foreign matter or water, if allowed to enter the ball screw, may increase friction and cause damage.

For example, the entry of chips or cutting oil may be expected with machine tools depending on the work environment. Where entry of foreign matter is anticipated, use a bellows or telescopic cover as shown in fig. to cover the screw shaft completely.

Dust Proof Method

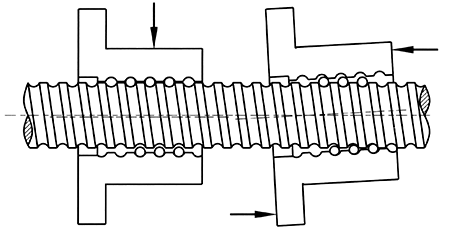

Dust Proof MethodOffset load

When offset load phenomenon occurs, screw life and noise tend to be directly affected, which would usually be accompanied with hand feel of rough running. In the event unload running and running right after assembling demonstrate different degree of cases, this should be ascribed to the poor assembly accuracy which will produce offset load phenomenon as shown in Fig.

Offset load

Offset load