Application of ballscrew

1 Automatic Industrial.

2 Semi-conductor Industrial.

3 Industrial mechanism.

4 Medical equipment

Characteristic of ballscrew

1 Coefficient of friction.

2 Precision of position.

3 Effective duration.

4 High speed tuning & both forward and reverse.

5 Element of linear and swiveling.

Nut Types

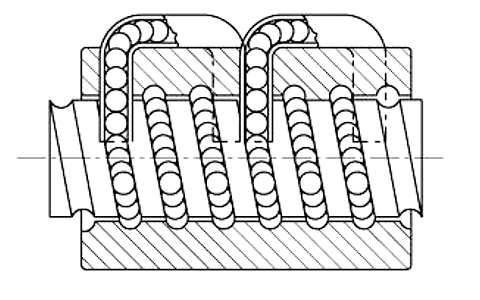

T-type Nut

For the circulation of this type, the steel balls roll forward along the grooves between the screws and the nut, then are picked up at the front end of the external circulation tube, which further pass through the circulation tube and circle around to the other end of the circulation tube, finally return to the origin point. It is generally provided with several rolls of steel balls and a single pass circulation tube, both routing type and projecting tube type of profile may be adopted.

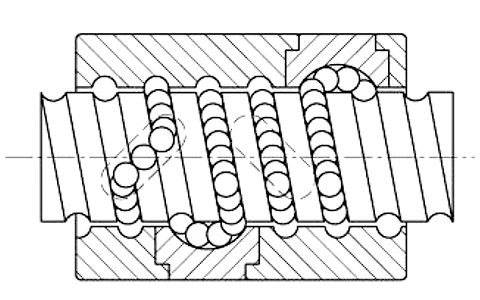

I-type Nut

In this type, the steel balls move along the grooves of the internal circulator, diagonally pass over the tooth tops of the screws, then return to the origin point. It generally possesses one roll of steel balls and one single pass circulation. This type of screws has at least one end with completely through threading, suitable for screws of smaller diameters, it is equipped with metal circulator.

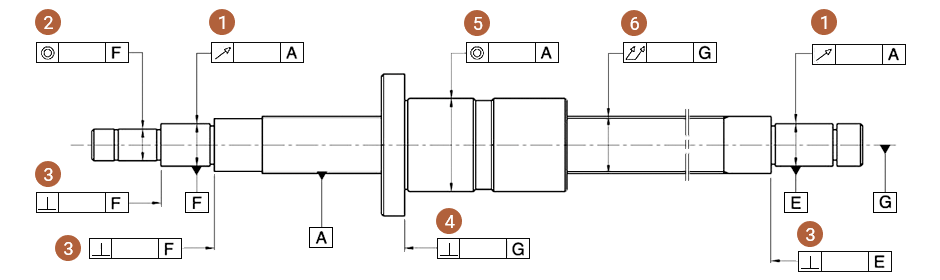

Definition of Mounting Accuracy and Tolerances on Ball Screw

To use a ball screw properly dimensional accuracy and tolerances are most important. It will help you determine the tolerance factors as they are subject to change according to accuracy grade.

1 Periphery run-out of the supporting part of the screw shaft to the screw groove.

2 Concentricity of a mounting portion of the shaft to the adjacent ground portion of the screw shaft.

3 Perpendicularity of the shoulders to the adjacent ground portion of the screw shaft.

4 Perpendicularity of the nut flange to the axis of the screw shaft.

5 Concentricity of the ball nut diameter to the screw groove.

6 Parallelism of the mounting surface of a ball nut to the screw groove.

7 Total run-out of the screw shaft to the axis of the screw shaft.

Accuracy of the Mounting Surface

Note : For the overall radial runout of the screw shaft axis, refer to JIS B 1192-1997. Fig Accuracy of the Mounting Surface of the Ball Screw.

Recommended accuracy grade for machine applications

| Application | Axis | Accuracy Grade | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 7 | PR1 | PR2 | PR3 | |||

| CNC Machine | Lathe | X | ||||||||||

| Z | ||||||||||||

| Milling Machine Boring Machines | X | |||||||||||

| Y | ||||||||||||

| Z | ||||||||||||

| Machine Center | X | |||||||||||

| Y | ||||||||||||

| Z | ||||||||||||

| Jig Borers | X | |||||||||||

| Y | ||||||||||||

| Z | ||||||||||||

| Drilling Machine | X | |||||||||||

| Y | ||||||||||||

| Z | ||||||||||||

| Grinding Machine | X | |||||||||||

| Y | ||||||||||||

| Electro-discharge Machine (EDM) | X | |||||||||||

| Y | ||||||||||||

| Z | ||||||||||||

| Wire Cut (EDM) | X | |||||||||||

| Y | ||||||||||||

| U | ||||||||||||

| V | ||||||||||||

| Laser Cutting Machine | X | |||||||||||

| Y | ||||||||||||

| Z | ||||||||||||

| General Machinery | Punching Press | X | ||||||||||

| Y | ||||||||||||

| Single Purpost Machines | ||||||||||||

| Wood working Machines | ||||||||||||

| Industrial Robot (Precision) | ||||||||||||

| Industrial Robot (Precision) | ||||||||||||

| Coordinate Measuring Machine | ||||||||||||

| Non-CNC Machine | ||||||||||||

| Transport Equipment | ||||||||||||

| X-Y Table | ||||||||||||

| Linear Actuator | ||||||||||||

| Aircraft Landing Gear | ||||||||||||

| Airfoil Control | ||||||||||||

| Gate Valve | ||||||||||||

| Power steering | ||||||||||||

| Glass Grinder | ||||||||||||

| Surface Grinder | ||||||||||||

| Induction Hardening Machine | ||||||||||||

| Electromachine | ||||||||||||